charpy impact testing methods|charpy impact test formula : warehouse The apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the material can be inferred by comparing the difference in the height of the hammer before and after the fracture (energy absorbed by the fracture event). Resultado da stephany ribeiro (55 results) Report. Related searches agatha ludovino casey cumz melissa devassa louna melissa pitanga this is why you come to columbia jefao stefanie gih rocha alix lynx pov coroa gostosa julia mattos daisy bean luiza marcato avril santana stephany rocco siffredi swallow .

{plog:ftitle_list}

Videos for: torrent cherry crush. Most Relevant. HD. 2 085 views. 11:42.

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .

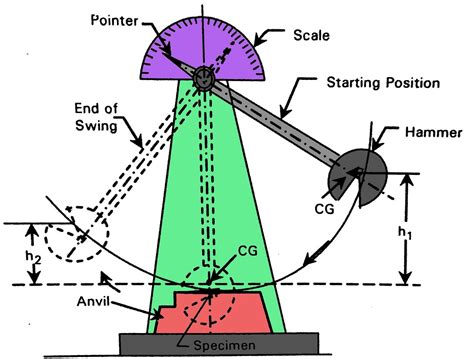

The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be used as an economical quality control .The apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the material can be inferred by comparing the difference in the height of the hammer before and after the fracture (energy absorbed by the fracture event). Charpy Impact Testing, also known as the “Charpy V-notch test,” is a standardized test method used to determine the impact toughness of materials, particularly .The four most common impact-test procedures in use around the world are probably ISO 148 “Steel— Charpy impact test V-notch ,” ASTM E 23 “Standard Test Methods for Notched Bar .

charpy impact testing procedure

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the .According to the standard test methods, the Charpy or Izod impact test can be employed to investigate the behavior of specified types of specimens under the impact conditions defined .The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .

The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the . 5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce vibration or .The standard test method for the Charpy impact resistance of FRP composites can be found in ASTM D6110 [51] and EN ISO 179 [52]. This test method can be performed in a fully automated way with a small technical effort, and the specimen can be inexpensively machined. However, the specimen is a short and thick beam, which may not be .

useful in the development of a standardized test method for Charpy impact testing of cementitious composites. The Charpy Test The Charpy impact test relies on the potential energy of a weighted pendulum as shown in Fig. 1. The pendulum is raised to some initial height h i, which is measured from the center of mass to the datum. The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm. 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .

Four types of impact testing are described in detail below, encompassing the pendulum, drop-weight, and dynamic tear methods: 1. Charpy. The Charpy impact test, also known as the V-notch test, is a type of impact test where a weighted pendulum hammer is released from a specified height and strikes the part. A Charpy impact testing apparatus, a .The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus This test determines the amount of .

Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads. These characteristics are vital for selecting materials that meet specific application requirements, resulting in safer and more .

Charpy Impact Test: In this method, a test specimen is held at one end and struck on the opposite end with a pendulum hammer. The amount of energy absorbed by the specimen during fracture is measured. Izod Impact Test: This test method is similar to the Charpy impact test, but the specimen is held vertically, and the hammer strikes the specimen on the same side as .The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materialsThese test methods of impact testing relate specifically to the behavior of metal when subjected to a single application of a force resulting in multi-axial stresses associated with a notch, coupled with high rates of loading and in some cases with high or low temperatures. . At WMT&R Izod and Charpy impact testing are performed on .

Abstract. Several researchers have recently employed the Charpy method to characterize the high strain rate mechanical strength of cementitious composites. This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen sizes and geometries. .Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test machine is released to strike a notched specimen, and the amount of energy absorbed during the break is calculated. A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after .

Methods for Notched Bar Impact Testing of Metallic Materials (E 23) has over the years been to standardize and control the variables associated with impact testing. This report looks at the history of impact testing, with emphasis on the key advances in understanding and application of the impact test, as reflected in the evolution of the testCHARPY IMPACT TESTING IZOD IMPACT TESTING Tested Materials Plastics Plastics Types of Notches (0.25mm) Preferred V-notch V-notch . ASTM test method does not use a square at the end of the unit. DATA SHEET CONVERSION FACTOR Impact ISO Unit ASTM Unit ISO to ASTM ASTM to ISO Charpy kJ/m² ft-lb/in * by 0.476 * by 2.1 Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . 3 A Novel Method for Accurate SoC Estimation in LiFePO4 Batteries. Charpy testing is a method for determining the relative impact strength of metals. It is also known as Charpy V notch test. . The Charpy impact test can adequately detect this brittle-toughness transition temperature, providing key data on the material’s limits of use. It must be noted, however, that the Charpy test is less useful for .

Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’s tests used a pendulum impact machine based on the design developed .IMPACT TESTING MATTERS, NOW MORE THAN EVER 1.1 What is a Pendulum Impact Test An impact test determines a material’s resistance to an impact event. It measures the amount of energy the material absorbs when it is hit by a high-rate load. The most common impact test methods are Charpy and Izod and are typically run using a pendulum impact tester.

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.What is Charpy Impact Testing? The Charpy impact test was developed by S.B. Russell and Georges Charpy, at the turn of the 20th century. It remains, to this day, one of the most popular impact testing methods due to the relative ease of creating samples and obtaining results.

charpy impact test sample

Standard Test Methods for Notched Bar Impact Testing of Metallic Materials,5 and ISO 148-2, Metallic Materials – Charpy Pendulum Impact Test – Part 1: Test Method,7 consists of a physical part (direct verification) and an experimental part (indirect verification). The direct verification consists in the detailed evaluation ofCharpy and Izod Impact Testing The Charpy or the Izod impact test is carried out by testers using a pendulum impact testing apparatus. A device having a swinging pendulum that is released to strike a secured specimen is referred to as a pendulum impact testing machine or a pendulum impact tester. . ASTM E572 test method covers the analysis of .

The two most basic and well known impact pendulum testers for plastic materials are the Izod and Charpy. These plastic impact test methods measure the energy absorbed by the specimen caused by the impact to create failure. These test are typically pass/fail tests: They give the average impact energy required to break the samples. .

charpy impact test requirements

charpy impact test formula

hard drive test windows server 2008 r2

Resultado da Busty stepmom pleasured by naughty teen. 6 min Ordinaryscrutin -. 9,007 madrasta safada FREE videos found on XVIDEOS for this search.

charpy impact testing methods|charpy impact test formula